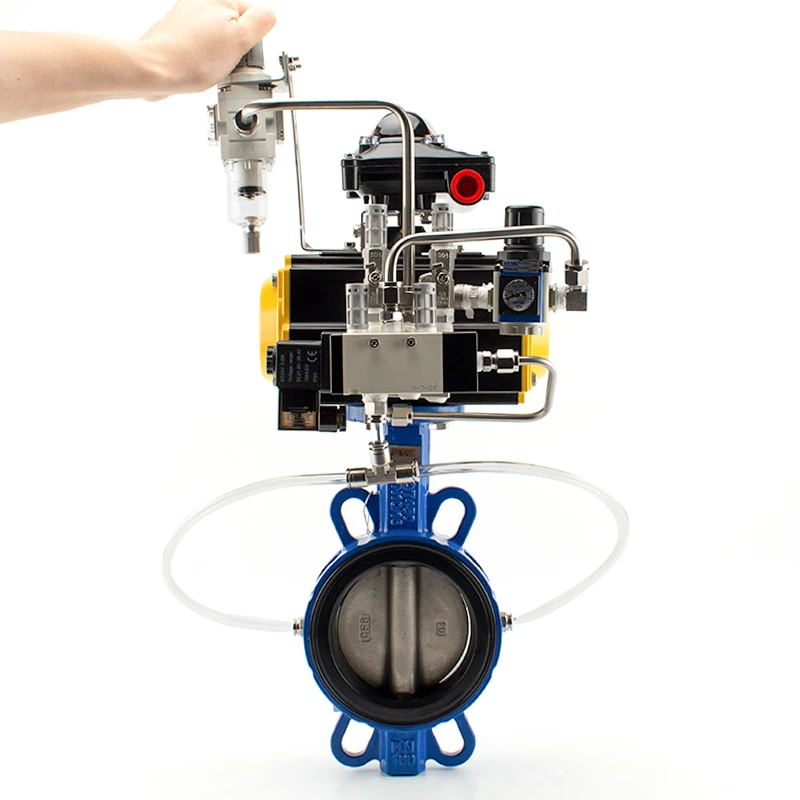

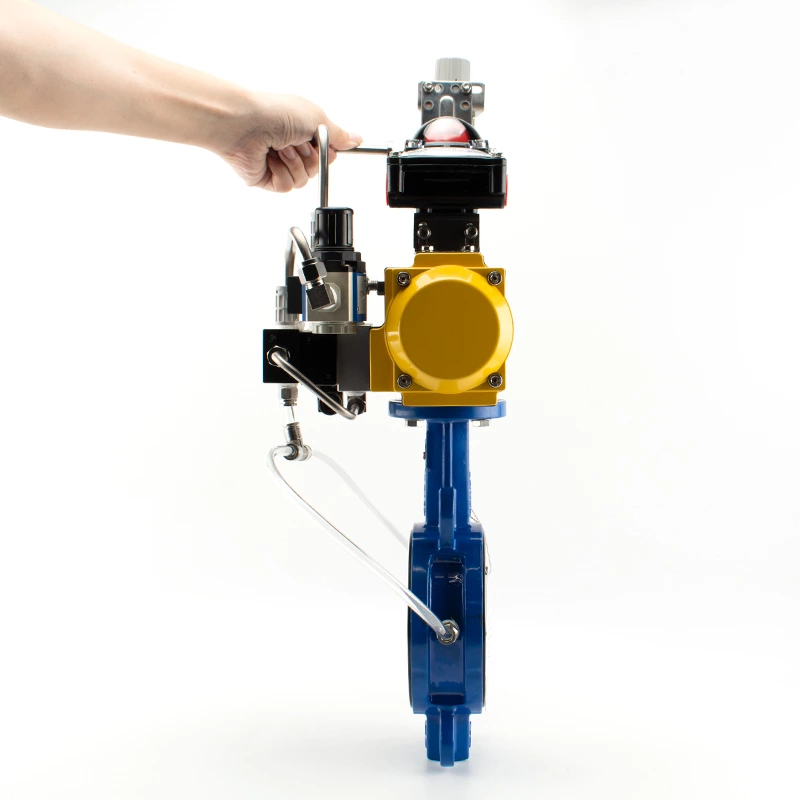

Stainless Steel Inflatable Expansion Butterfly Valve For Lithium Battery Industry

- Material:

- ASTM A536 65-45-12, WCB, CF8M

- Specification:

- DN50-DN1000

- Gasket:

- EPDM, NBR, FRM, PTFE

Stainless Steel Inflatable Expansion Butterfly Valve For Lithium Battery Industry

The design of the expansion butterfly valve uses gas pressure to extend the valve seat toward the valve disc to provide a smooth distribution of pressure to the seal at all times. Since only momentary contact occurs between the valve disc and the valve seat during the opening and closing of the valve, the valve disc is only slightly bumped.

On the contrary, for the general butterfly valve, the collision caused by the valve disc rubbing the valve seat will reduce the performance and life of the valve.

Pneumatic expansion valve is a kind of valve which can achieve close sealing by compressed air. It is suitable for handling dust, bulk mate-rials, slurry, chemical powder, cement, quartz sand, fly ash, ceramics, carbon powder, dust, precious metal powder, etc.

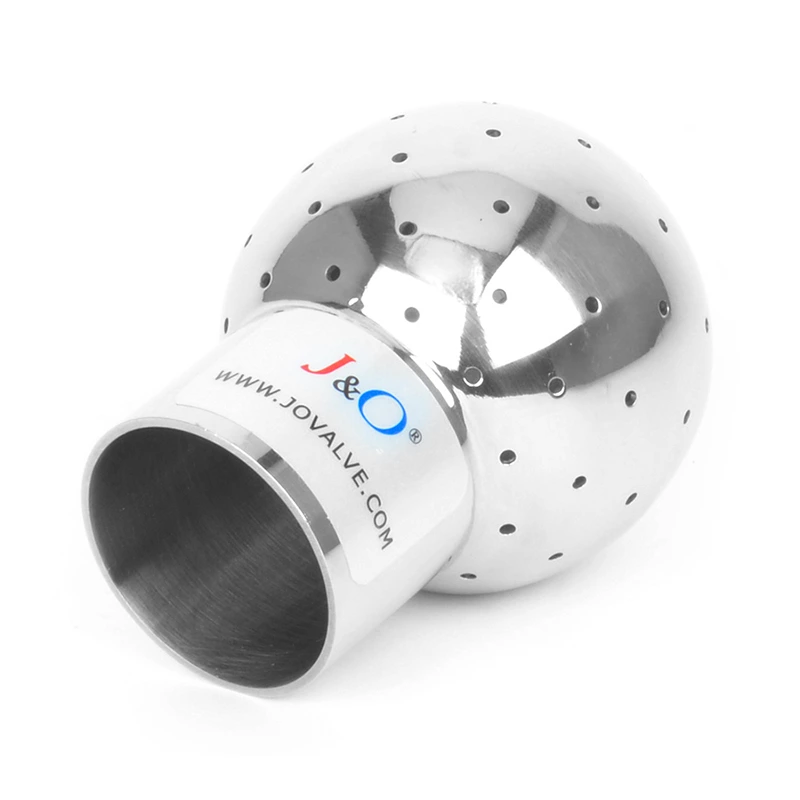

When the valve plate of pneumatic expansion butterfly valve is in the state of loose sealing ring (non expansion), a fixed gap is formed between the sealing ring and the valve plate.

When the compressed air enters the back of the sealing ring, the surface of the sealing ring expands and clings to the surface of the valve plate to form an effective seal.

Before the valve is opened, the sealing ring is relaxed in advance to form a fixed clearance.

Inflatable Seat Design: The inflatable seat design provides excellent sealing performance and reduces wear and tear on the valve components, ensuring long service life and low maintenance costs.

Wide Range of Sizes: Available in sizes ranging from DN50 to DN1000, the inflatable seat butterfly valve can accommodate a variety of pipeline diameters and flow rates.

Various Material Options: The valve is made from a selection of high-quality materials, including ASTM A536 65-45-12, WCB, CF8M for the body, and material options like Nylon-coated ASTM A536 65-45-12, CF8, CF8M, 2507, and 1.4462 for the disc. This ensures compatibility with different media and operating conditions.

Multiple Seat Materials: The seat materials can be chosen from EPDM, NBR, FRM or PTFE, providing flexibility and compatibility with various fluids and operating temperatures.

Stainless Steel Components: The valve’s stem, lower stem, retainer, nuts, and screws are made from corrosion-resistant stainless steel for durability and long-lasting performance.