Santiary Punching Center Line Butterfly Valve

Santiary Punching Center Line Butterfly Valve

J&O sanitary Punching Center Line butterfly valves can adopt manual handle, pneumatic actuator and electric actuator. It has been carefully designed by our technical department and precisely manufactured by our production department, and have been widely used and praised by users.

The valve has a wide range of applications: fluid on/off or regulation control in food, biopharmaceutical, dairy beverages, urban water supply, brewing, fine chemicals, water treatment and air treatment industries.

Due to the use of a bracket connection structure, the valve can be equipped with valve electric actuators and pneumatic actuators, which can realize remote automatic control of the valve.

Pneumatic Actuators

Double action: When air inflow, it is opened, When air inflow again, it is closed, the current position is maintained when the air source fails.

Single-acting air-opening type: When air inflow, it is opened, when air cut-off, it is closed, air source failure, it will be closed.

Single-acting air-off type: When air inflow, it is closed, when air cut-off, it is opened, and when air source fault,it will be opened.

Optional accessories: reversing solenoid valve, limit switch, air filter pressure reducing valve, electric positioner, hand-wheel mechanism, position retaining valve.

The electrical part can choose explosion-proof

Electric Actuators

Switch type: Feedback signal: passive contact signal\4-20mA\resistance signal.

Adjustment type: input signal 4-20mA\0-10V\1-5V; feedback signal: 4-20mA\0-10V\1-5V.

Voltage: AC220V\380V\110V\24V, DC12V\24V, etc.: If you need special voltage, it can be customized.

Explosion-proof grade: optional explosion-proof type EXdIIBT4.

Product Advantages

- Butterfly valve rubber sealing ring and valve plate are made of high-quality stainless steel and sanitary materials, which ensure the performance and service life of the butterfly valve, as well as sanitation and environmental protection.

- It is manufactured by high-precision CNC numerical control equipment, so it has reliable interchangeability of the butterfly valve components, meanwhile, it can eliminating the disadvantage of affecting the performance of the butterfly valve due to the replacement of rubber.

- The valve stem is inlaid with a nylon bushing, which reduces friction and makes the valve open flexibly and lightly.

- The valve body is made of stainless steel, and the sealing rubber is made of food-grade rubber, which is hygienic and environmentally friendly.

- The diameter of the valve body is equal to the inner diameter of the pipeline. When opening, the narrow and streamlined valve plate is consistent with the direction of the fluid. The flow rate is large, the resistance is small, and there is no material accumulation.

- The manual handle adopts toggle type, which can bear large operating torque and is also not easy to break.

- The valve opening and closing range is 0~90 degrees, and it can be fixed at every 15 degrees. It is adjustable, and the switch is quick and easy to operate.

- The valve body adopts detachable connection, the structure is simple, and the maintenance is convenient.

- The shape is light and beautiful, the surface is smooth, and there is no dead angle for hygienic cleaning.

- The product quality is ensured, after strict strength and sealing tests.

- Sampling for no less than 30,000 fatigue life tests to ensure its service life.

- The stamping butterfly valve body adopts the precision stamping forming process, which saves the material, light weight, saves the manufacturing cost and low price.

Product Description

| Product Name: | Sanitary Punching Center Line Butterfly Valve |

| Valve model: | D6/981F |

| Nominal diameter: | D15-D300 |

| Nominal pressure: | PN10-PN16 |

| Body material: | SS304,SS316L |

| Availably connection: | Clamped |

| Pressure rating: | 150LB |

| Structural form: | Straight-through |

| Structure length standard: | Enterprise standard |

| Pressure test standard: | GB/T13927-2008 |

| Seat material: | PTFE:-20°~150°, PPL+PTFE:-30°~250° |

| Seal max temperature: | 150 degrees |

| Valve leakage: | Zero leakage |

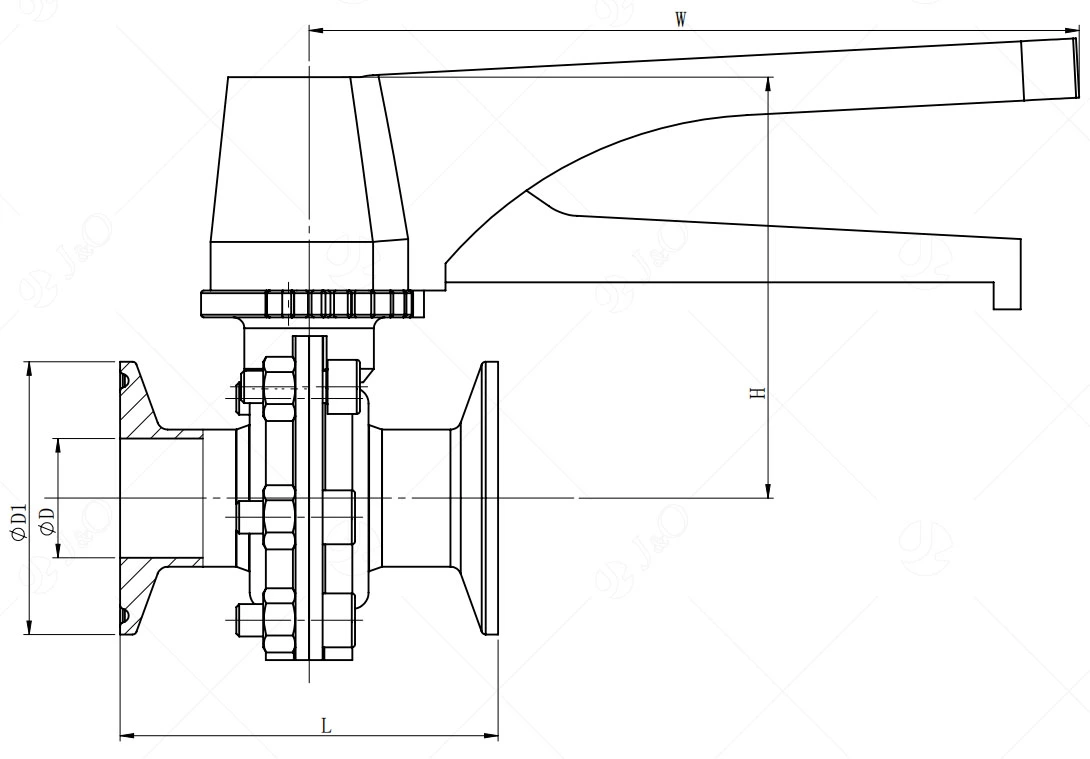

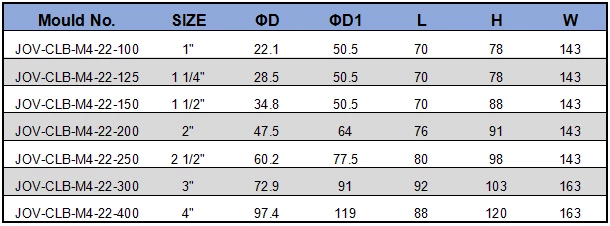

Product Dimensions